- By First Alliance Logistics Management

- June 2, 2025

- Buying Pallets

Wooden pallets are an integral and necessary part of modern supply chain systems, primarily enabling the transportation of goods across the world. Though they might be a second thought for some, others understand their true impact after implementing them in their operations.

Understanding a pallet’s full life cycle sheds light on its production, utility, reuse, and environmental impact. By examining the entire life cycle, businesses can identify opportunities for more cost-effective pallet management, while ensuring compliance with sustainability goals. Gain in-depth insights and demystify the life cycle of a wood pallet; uncover each stage, from creation to repurpose.

The Journey’s Beginning: Manufacturing Wooden Pallets

The life cycle of a wooden pallet begins with sourcing the right materials and manufacturing them into the sturdy, reliable structures used in modern logistics. We will explore the process from tree to pallet, optimizing the materials and design for the best performance in the supply chain.

Sourcing and Preparing the Wood

A standard wooden pallet begins its life in the forest. Manufacturers source southern yellow pine, oak, and other hardwoods to serve as raw material. Regions that rely heavily on wooden pallet production often sustain their operations by utilizing wood from trees not deemed fit for high-grade furniture or construction. These sources ensure efficient resource utilization without wasting valuable timber.

Ensuring Quality and Compliance: Assembling and Treating Pallets

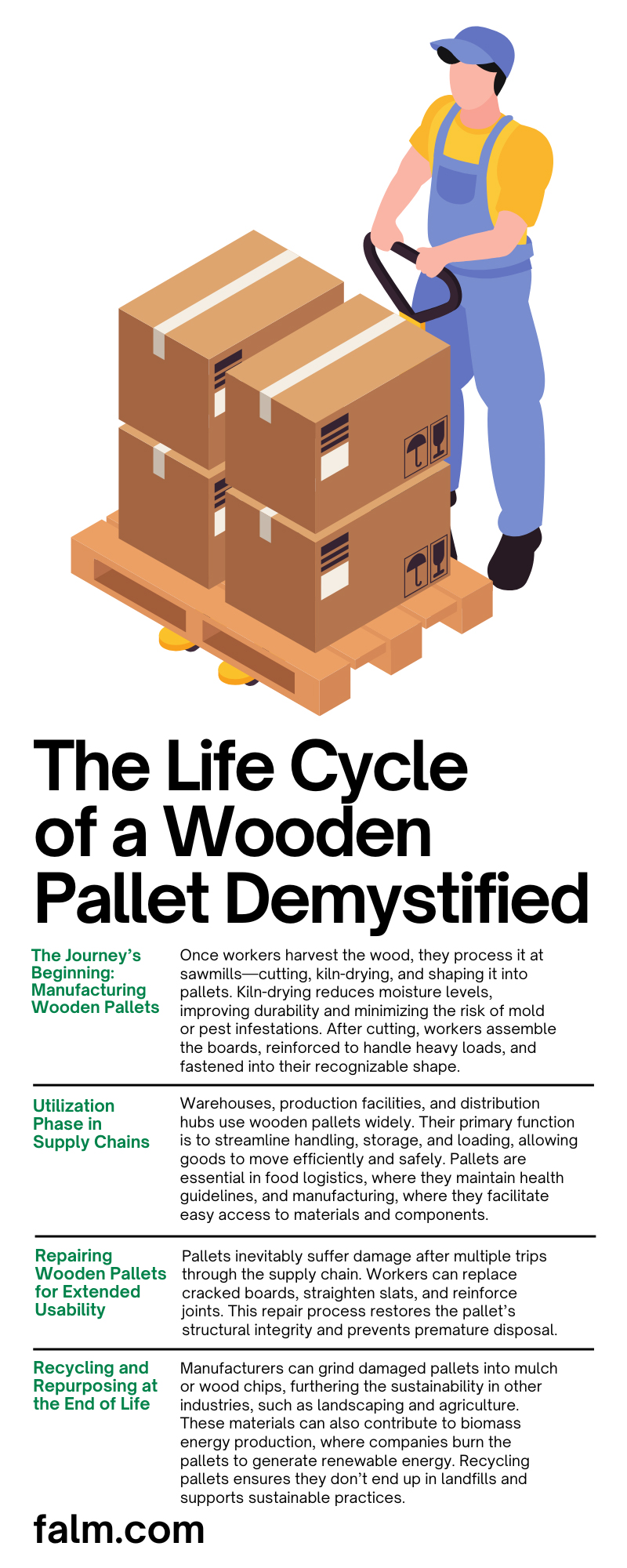

Once workers harvest the wood, they process it at sawmills—cutting, kiln-drying, and shaping it into pallets. Kiln-drying reduces moisture levels, improving durability and minimizing the risk of mold or pest infestations. After cutting, workers assemble the boards, reinforced to handle heavy loads, and fastened into their recognizable shape.

Some pallets undergo heat treatment or fumigation to meet international shipping regulations and prevent pest migration.

This quality assurance is where a pallet distributor comes into the equation. Their responsibility extends beyond production, as they source pallets in bulk and help industries acquire them for specific shipping or warehouse needs. Companies that partner with a reliable distributor can acquire access to well-manufactured pallets that meet industry standards.

Utilization Phase in Supply Chains

After manufacturing, wooden pallets begin their role in the supply chain. They serve multiple functions, including improving storage efficiency and facilitating easier transportation of goods. In this section, we examine how industries utilize pallets to streamline logistics operations.

Pallets in Action: Supporting Storage, Handling, and Transport

Warehouses, production facilities, and distribution hubs use wooden pallets widely. Their primary function is to streamline handling, storage, and loading, allowing goods to move efficiently and safely. Pallets are essential in food logistics, where they maintain health guidelines, and manufacturing, where they facilitate easy access to materials and components.

Maximizing Lifespan: How Usage and Conditions Impact Pallet Durability

The end of this usage phase varies. High-quality pallets reused under regulated conditions may last for years with proper maintenance. However, exposure to harsh conditions, mishandling, and natural wear-and-tear often reduces their lifespan, leading to the next stage of their life cycle.

Repairing Wooden Pallets for Extended Usability

Manufacturers design wooden pallets to withstand wear and tear, but they may need repairs over time. However, their simple design allows for easy fixes that extend their lifespan and reduce waste.

The Pallet Repair Process: Restoring Value and Extending Lifespan

Pallets inevitably suffer damage after multiple trips through the supply chain. Workers can replace cracked boards, straighten slats, and reinforce joints. This repair process restores the pallet’s structural integrity and prevents premature disposal.

Sustainability and Cost-Savings: The Benefits of Pallet Repair

Repairing pallets saves businesses money and supports sustainability by reducing waste. Many pallet repair operations incorporate reused wood from damaged pallets, further minimizing the environmental impact. Frequent inspections ensure pallets remain safe and compliant with industry regulations.

Recycling and Repurposing at the End of Life

Eventually, every wooden pallet reaches the point where it can no longer serve its original purpose. However, businesses can recycle or repurpose these pallets into valuable products instead of discarding them.

Recycling Pallets: Turning Waste Into Useful Resources

Manufacturers can grind damaged pallets into mulch or wood chips, furthering the sustainability in other industries, such as landscaping and agriculture. These materials can also contribute to biomass energy production, where companies burn the pallets to generate renewable energy. Recycling pallets ensures they don’t end up in landfills and supports sustainable practices.

This comprehensive approach to pallet management improves operational efficiency and aligns with the growing global focus on sustainable practices in logistics.

Repurposing Pallets: Creative Solutions for a Sustainable Future

Another form of recycling involves repurposing pallet wood for creative applications, such as furniture, décor, and architectural elements. Repurposing pallets encourages sustainability by reducing the need for new raw materials and promoting the reuse of existing resources.

The Role of Wooden Pallets in a Sustainable Future

As sustainability becomes a focal point for industries worldwide, wooden pallets are evolving to meet the demands of eco-conscious consumers and businesses. The emphasis on sustainability is reshaping how industries view wooden pallets.

Eco-Friendly Practices and Sustainable Sourcing

The pallet industry has embraced eco-friendly practices, including responsible wood sourcing. Companies now prioritize sustainable harvesting and using renewable resources to ensure that the wood used in pallet production reduces the overall environmental impact of supply chain operations.

The Growing Demand for Renewable Resources and Recyclable Pallets

The demand for renewable and recyclable products is growing, highlighting the long-term viability of wooden pallets. As businesses align their operations with sustainability goals, incorporating recyclable pallets into supply chains reduces environmental impact. Wooden pallets embody efficiency, adaptability, and responsibility in modern supply chains.

Partnering for Sustainable Logistics Success

Sustainable logistics relies on effective partnerships and efficient management of pallet systems. Understanding the life cycle of wooden pallets offers valuable insights for supply chain managers and logistics coordinators. Trusted pallet suppliers form strategic partnerships to ensure that every stage of the process, from production to recycling, is efficient and sustainable.

How First Alliance Logistics Management Supports Sustainable Operations

First Alliance Logistics Management is a professional pallet distributor that offers custom pallet solutions to meet your company’s needs. Our expertise helps your business thrive while prioritizing sustainability, whether you need a reliable partner for pallet supply, pooling management, or enhanced recycling practices.

Contact us today to learn how First Alliance Logistics Management can optimize your logistics operations with professionalism, quality, and sustainability at the forefront.