- By First Alliance Logistics Management

- October 14, 2025

- Buying Pallets

You walk into a warehouse and you see that they use every square foot, every pallet is within easy reach, and the whole operation runs like clockwork. Achieving this level of efficiency starts with having the right pallet racking system.

We’ll help you set up your storage properly and solve some of your biggest headaches, no matter if you are managing a growing e-commerce operation or overseeing a cold storage facility. Say goodbye to time wasted hunting for inventory, dealing with safety risks from unstable stacks, and the stress of running out of space. Our guide will break down everything you need to know about pallet racking systems so you can make the best choice for your operation.

What Are Pallet Racking Systems?

Pallet racking systems are storage solutions that organize and store goods on pallets. They use both vertical and horizontal space, increasing your warehouse footprint and storage availability. Essentially, they bring order to the chaos inside a warehouse, giving every item its proper place that allows safe and efficient access for your team.

No matter the size or complexity of your space, there’s a racking system to match. You can have a straightforward setup for small operations or a highly engineered system made for demanding industries that are hard on their equipment. Pallet racks and pallet suppliers are what truly make a warehouse efficient.

Types of Pallet Racking Systems

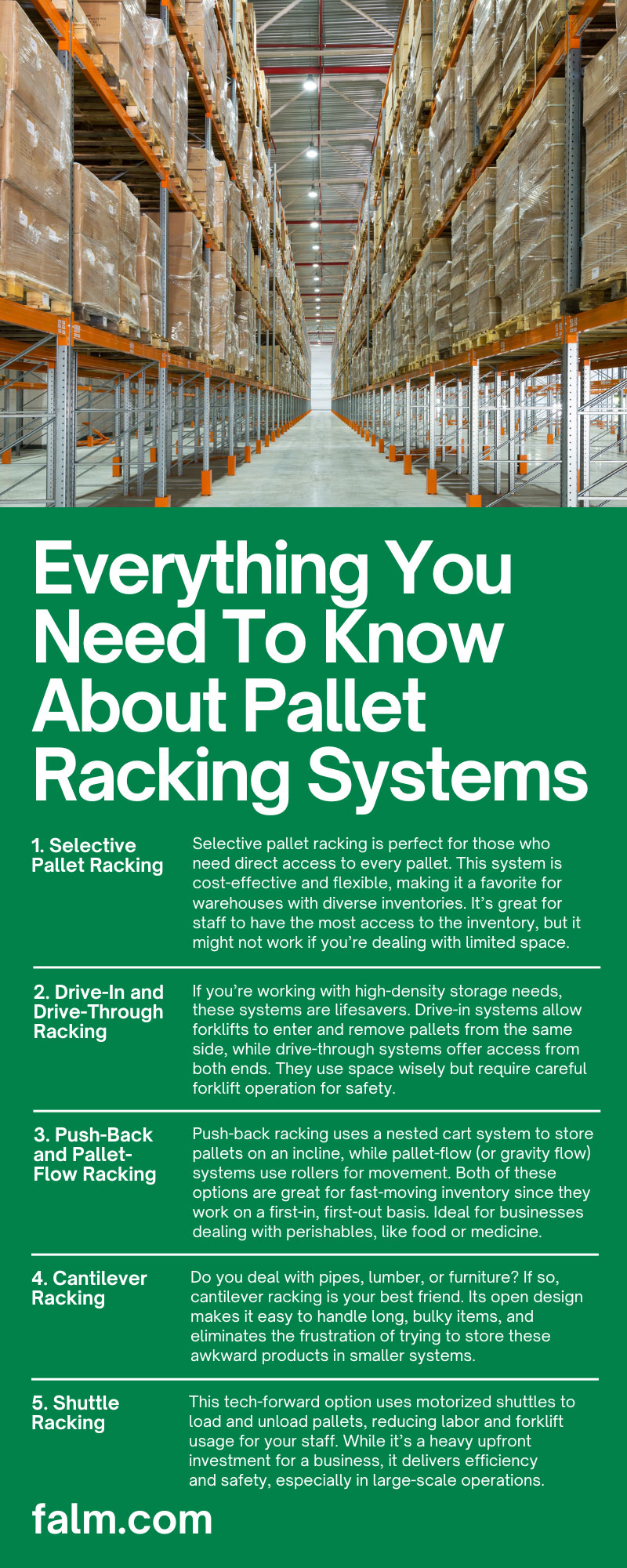

When it comes to choosing a racking system, you’ve got options. Here’s a quick look at the most common types and what they’re good for.

1. Selective Pallet Racking

Selective pallet racking is perfect for those who need direct access to every pallet. This system is cost-effective and flexible, making it a favorite for warehouses with diverse inventories. It’s great for staff to have the most access to the inventory, but it might not work if you’re dealing with limited space.

2. Drive-In and Drive-Through Racking

If you’re working with high-density storage needs, these systems are lifesavers. Drive-in systems allow forklifts to enter and remove pallets from the same side, while drive-through systems offer access from both ends. They use space wisely but require careful forklift operation for safety.

3. Push-Back and Pallet-Flow Racking

Push-back racking uses a nested cart system to store pallets on an incline, while pallet-flow (or gravity flow) systems use rollers for movement. Both of these options are great for fast-moving inventory since they work on a first-in, first-out basis. Ideal for businesses dealing with perishables, like food or medicine.

4. Cantilever Racking

Do you deal with pipes, lumber, or furniture? If so, cantilever racking is your best friend. Its open design makes it easy to handle long, bulky items, and eliminates the frustration of trying to store these awkward products in smaller systems.

5. Shuttle Racking

This tech-forward option uses motorized shuttles to load and unload pallets, reducing labor and forklift usage for your staff. While it’s a heavy upfront investment for a business, it delivers efficiency and safety, especially in large-scale operations.

Key Components of Pallet Racking Systems

All pallet racking systems consist of core components that ensure their functionality and safety:

- Frames and Beams: These form the backbone, holding up heavy loads with strength and stability.

- Decking: Add-ons like wire mesh decks can make your system more versatile by securely holding smaller items.

- Safety Accessories: Guardrails, column protectors, and safety bars minimize risks and protect investments in high-traffic areas.

Use these components to customize your system to meet your exact needs.

Space and Safety Benefits

One of your biggest challenges may be gridlocked floor space or concerns about worker safety. The right pallet racking system tackles these issues head-on. Organize your space vertically, and you’ll free up the aisles for smooth traffic flow.

With proper safety measures like rack guards and even load distribution, you can also reduce the risks of accidents and product damage. For operations where precision is everything, custom solutions—like specialized racks that tolerate freezing temperatures and high moisture content—can keep things running efficiently, even in challenging environments.

Choosing the Right System for Your Needs

Selecting a pallet racking system isn’t a one-size-fits-all decision. Ask yourself the following questions to figure out what will work best for you.

What Are You Storing?

Are the items you’re storing light? Are the pallets heavy? Do you have bulky or irregularly shaped inventory? This will determine how much weight your racking systems may have to endure.

How Much Space Do You Have?

Assess your warehouse height as well as floor space to determine what will fit best where and how best to use your warehouse.

What’s Your Throughput Demand?

This aspect will influence the high-speed operations you may need for flow systems, while a static inventory benefits more from simple, selective racks.

By answering questions like these, you can make a decision that streamlines your workflow, improves productivity, and prepares your warehouse for the future.

Maximizing Efficiency Over Time

Even the best racking system requires maintenance. Regular inspections and weight checks can prevent structural damage or potential failures in your system. Also, make sure to train your team to operate forklifts safely within the racks to protect both employees and inventory.

Looking to go even further? Consider pairing your racking system with inventory management software or automated technologies, and partner with a reliable pallet supplier for easier ways to secure new and used pallets. These tools make it easier to track which products are where, saving you both time and hassle.

Why It Matters for Your Business

Still wondering why you should invest in a great pallet racking system? The answer is simple—it saves you money in the long run. Reduced labor costs, improved access to inventory, and fewer accidents mean smoother operations that directly impact your bottom line. As your storage needs grow, modular racking systems can evolve with you rather than holding you back.

The Last Word on Pallet Racking Systems

Now that you know everything you need to know about pallet racking systems, you can fix the missing puzzle piece for your warehouse. Once you have it in place, you’ll wonder how you managed without it. There’s a setup out there perfect for your needs.

At First Alliance Logistics Management, we know how important storage solutions are for your business. As a leading pallet supplier, we’re here to meet your pallet needs and help your entire operation. If you’re ready to create efficiency in your warehouse, reach out to us today. We’ll get you in a spot to take on anything your industry throws your way!