Pallets are vital parts of the fast-moving world of logistics and warehousing. Unfortunately, overloading a pallet or misjudging its strength can lead to damaged products, delayed shipments, or safety hazards for workers.

Understanding pallet weight limits and load-bearing capacity matters for anyone involved in storage or shipping. Gain more insight by learning the factors that affect pallet performance, from materials and load types to stacking practices and maintenance tips, and make your operations safer and more efficient.

Why Do Pallet Weight Limits Matter?

Pallet weight limits reflect the design and material strength of each pallet. Overloading a pallet doesn’t just risk breaking the pallet itself; it could also damage everything stacked on top and create hazards for the people moving it.

Weight limits also affect the storage and transport efficiency of pallets. An overloaded pallet may fail inspection or delay a shipment. Staying within the weight guidelines also helps business leaders comply with local and international shipping regulations and avoid fines and rejected shipments.

How Different Pallet Materials Affect Load Capacity

Pallets come in materials like wood, plastic, or metal, and each type has different load-bearing capabilities. Wooden pallets are the most common, especially the standard 48” x 40” size that can usually support up to 2,500 pounds. Hardwoods usually carry more weight than softwoods, and builders increase a pallet’s capacity by using thicker boards and more nails or screws. The wood type and construction method directly affect how much weight the pallet can safely support.

Plastic pallets are lightweight and resistant to moisture, making them popular in the food and pharmaceutical industries. However, they sometimes can’t carry as much weight as wooden pallets. Metal pallets stand out for their durability and high load capacity, but they are heavier and more expensive than wood and plastic options. Choosing the right material is about balancing cost, weight capacity, and the environment the pallet will work in.

Static vs. Dynamic Load Capacities

When evaluating pallets, it’s important to understand the difference between static and dynamic load capacities. Static load refers to the weight a pallet can hold when it sits on a warehouse rack or on the ground. Dynamic load, on the other hand, refers to how much weight a pallet can safely carry while moving, such as when a forklift lifts it or it’s transported on a conveyor.

Many accidents happen because a pallet might hold the weight when stationary but fail while moving. Knowing both limits can prevent accidents and product damage during all stages of handling.

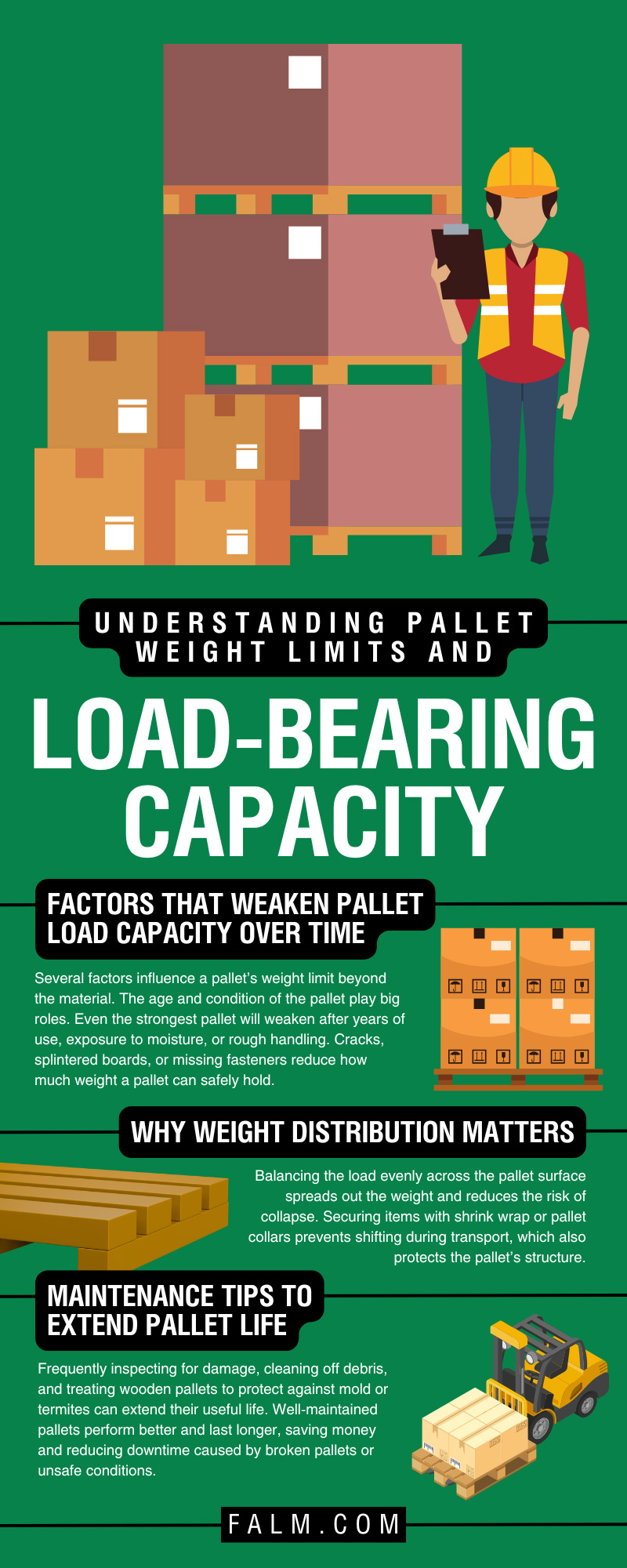

Factors That Weaken Pallet Load Capacity Over Time

Several factors influence a pallet’s weight limit beyond the material. The age and condition of the pallet play big roles. Even the strongest pallet will weaken after years of use, exposure to moisture, or rough handling. Cracks, splintered boards, or missing fasteners reduce how much weight a pallet can safely hold.

Regular inspections should be part of your routine to catch these signs before problems arise. The environment matters, too. Pallets exposed to rain, humidity, or chemicals may deteriorate quickly.

Why Weight Distribution Matters

How you distribute the weight on a pallet is just as important as how much weight it carries. Even if a pallet can carry a certain capacity, placing a heavy load in one spot can create stress points that cause damage or failure.

Balancing the load evenly across the pallet surface spreads out the weight and reduces the risk of collapse. Securing items with shrink wrap or pallet collars prevents shifting during transport, which also protects the pallet’s structure.

Matching Pallets to Load Types

The load type affects what kind of pallet you need. Uniform loads, like neatly stacked boxes of similar sizes, distribute weight evenly and are easier on pallets.

In contrast, point loads—where heavy objects rest on small areas—require strong, reinforced pallets to prevent damage. Irregularly shaped or custom loads might need special pallets or tailored solutions to fit properly. Tapping into national pallet solutions helps business owners find the best pallet design for their needs, reduce risks, and improve handling efficiency.

Industry-Specific Load Requirements

Some industries have different pallet requirements than others. For example, workers in the food and beverage industry often move heavy glass bottles, demanding pallets that won’t bow or crack under pressure. Moving automotive parts, such as engines and tires, also requires heavy-duty pallets.

Meanwhile, retail businesses might prioritize lightweight yet sturdy pallets that protect products while facilitating stacking and transportation. Recognizing these unique industry needs guides smart pallet choices that reduce damage and streamline logistics.

Maintenance Tips To Extend Pallet Life

It’s important not to overlook pallet maintenance because even the best pallets lose strength without regular care.

Frequently inspecting for damage, cleaning off debris, and treating wooden pallets to protect against mold or termites can extend their useful life. Well-maintained pallets perform better and last longer, saving money and reducing downtime caused by broken pallets or unsafe conditions.

How To Assess Your Pallets’ Load Capacity

Checking a pallet’s load capacity can be straightforward if manufacturer markings or labels are visible. However, many pallets in circulation lack clear information. In these cases, reaching out to pallet experts or providers of national pallet solutions can provide guidance. They can assess the condition and capacity of pallets, run tests with different loads, and recommend the right pallets for specific applications.

Make Smarter Pallet Decisions Today

By understanding pallet weight limits and load-bearing capacity, you gain greater control over the safety and efficiency of your supply chain. Correctly matching pallets to loads, balancing weight, maintaining equipment, and using expert resources lead to fewer accidents and product damage, as well as smoother shipping processes. Whether managing a warehouse, coordinating shipments, or designing supply chain systems, you must pay attention to pallet performance.

If you are ready to improve pallet management and streamline logistics, First Alliance Logistics Management offers hassle-free pallet sourcing, recycling, and expert guidance through our network of national pallet solutions. Partnering with experienced logistics professionals removes the guesswork and helps business leaders optimize their pallet usage, reduce costs, and keep operations running seamlessly.