- By falm

- July 9, 2021

- Buying Pallets, Logistic

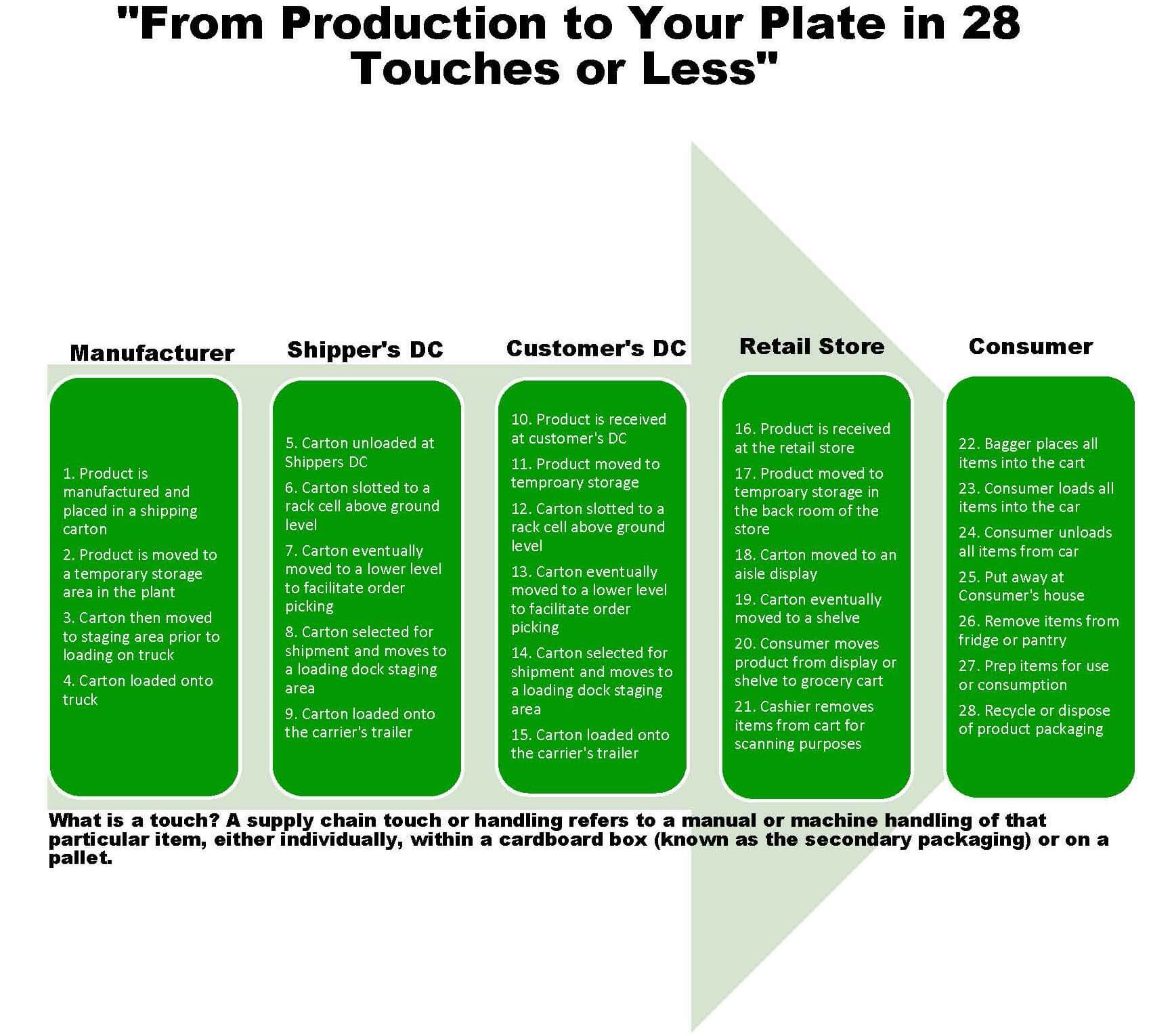

As you reach up to the supermarket shelf, have you ever thought about the number of “touches” or handlings involved in getting your favorite products from the production plant in another part of the country all the way to your shopping cart? It might startle you to realize that the jar of peanut butter you just picked up might be touched as many as 28 separate times by the time it reaches your kitchen.

What is a touch?

A supply chain touch or handling refers to a manual or machine handling of that particular item, either individually, within a cardboard box (known as the secondary packaging) or on a pallet. There are a lot of those touches involved in the grocery supply chain and they happen rapidly, to ensure that your supermarket shelf is rarely out of your favorite products.

There is even greater urgency for perishable goods such as bakery items or fresh produce. Fresh berries, for example, begin to die as soon as they are picked. As such, it is particularly imperative that those sensitive goods move through the supply chain as quickly as possible to maximize their shelf life at the retailer as well as in your refrigerator.

Why do supply chain professionals focus on touches?

Logistics or supply chain operators spend a lot of time agonizing about those touches. Each one can add cost and delay to the distribution process, as well as having potential implications for product quality. For example, a warehouse order selector may pick 150 or perhaps 200 cases per hour, so each case pick has a cost related to direct and indirect labor, as well as overhead – like the cost of the material handling equipment involved and operating the warehouse. Likewise, a stocking clerk at the retail store places a certain number of products per hour on the shelf, and so there is a cost to that as well. And for sensitive products like bananas or apples, those touches can also compromise quality, so the fewer touches, the better. Bottom line, supply chain operators look to eliminate touches or to automate as many of them as they can in an effort to reduce costs, increase the speed of distribution, increase shelf life, and prevent product damage.

There have been many innovative approaches introduced to limit the number of touches. One of them is DSD (direct store delivery), an approach that eliminates touches at the retail distribution center by shipping directly from the manufacturer or the manufacturer’s distribution center to the retailer. The manufacturer sometimes provides their own personnel to stock and rotate products at the store, thereby helping the retailer to avoid these touches. DSD is often used for perishable goods, or in the case of club or big box stores, for the direct delivery of several pallets of fast-moving products.

At retail, the use of display-ready boxes or display-ready pallets can also help. Stockers place the open-top container directly onto the shelf rather than emptying it manually, dramatically reducing the need for stocking labor. And in the case of floor displays, the display pallet is placed directly onto the sales floor, once again eliminating the need for stocking touches.

From the packaging line to your pantry in 28 touches or less

When it comes to quantifying the number of touches in the grocery supply chain, there is no single answer. Depending upon the product, the manufacturer, or the retailer, the number of handlings can vary markedly. As mentioned above, DSD deliveries bypass the warehouse and are delivered directly to the store. Providers of perishable products such as baked goods may employ such an approach to ensure that it has more time available on the shelf rather than making its way through the supply chain.

But let’s return to those peanut butter jars that we mentioned at the beginning of this piece. In a typical retail supply chain, the cycle of touches might happen something like as follows.

At the production plant, those peanut butter jars are placed into a carton and palletized (1), and then placed into storage (2). The pallet of peanut butter jar is retrieved from storage and staged for shipment (3) and then loaded onto the truck (4).

At the shipper’s distribution center, the pallet of peanut butter jar is unloaded (5), placed into storage (6), and lowered to the pick location or to the loading dock for full pallet picks (7). Less than pallet quantities are then picked and staged (8) and loaded (9).

Moving on to the customer’s distribution center, pallets are once again unloaded (10), placed into temporary storage (11), then moved to a forward reserve location above the picking line (12), lowered to the picking line as needed (13) and then picked and staged (14) prior to loading onto a trailer for delivery to the store (15).

At the retail store, products are received (16), moved into backroom storage at the store (17), brought to the aisle (18) and placed on the shelf or incorporated into a display (19). The consumer then picks up those peanut butter jars and places them in their basket (20). The box of peanut butter jars is placed on the check stand belt where it is scanned and bagged (21).

The consumer then loads the bags into the basket (22) and into the car (23). The groceries are then carried into the house (24) and placed into the fridge or pantry (25). Products are then removed from the pantry (26) and then removed for food prep and/or consumption (27). The residual packaging is then placed in either the recycling bin or the trash (28). We have included a colored chart of this entire process below.

As mentioned above, this scenario is just one of many possibilities, but the point is that grocery products get handled a great many times in their journey from production plant to your plate. Sophisticated supply chain technologies and many skilled professionals play critical roles in ensuring that your favorite snack peanut butter are there when you crave them, shipped accurately, damage-free, and in a timely manner.

As a leading U.S. pallet management provider, First Alliance Logistics Management recognizes the importance of pallet sourcing for your supply chain. Why not contact First Alliance Logistics Management to find out how we can help optimize your operations and make every touch count.