Modest investments to improve pallet plant efficiency can help providers remain competitive and desirable workplaces without breaking the bank.

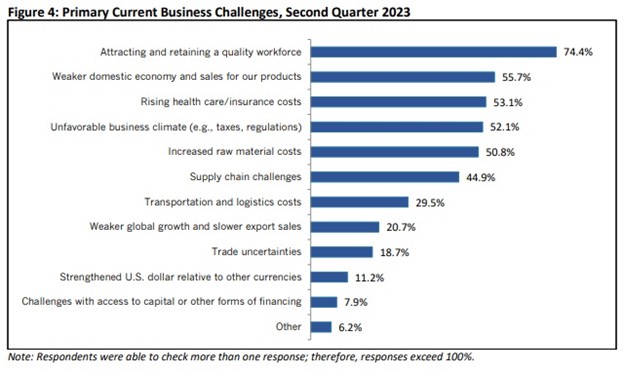

It isn’t just the pallet industry feeling the labor pinch. In fact, the latest NAM Manufacturers Outlook Survey identified the inability to attract and retain employees as far and away, the U.S. manufacturing sector’s biggest current headache. (See graph below.) Even with the economy slowing, there is no respite projected. The worker shortage will continue to bid wages upward with respondents saying they anticipate a pay hike of 2.9% over the next 12 months.

Source: NAM

Source: NAM

For pallet producers, the situation is similar to that faced by industry at large. Higher wages won during the COVID-19 pandemic seem here to stay. The labor shortage continues to fuel interest in plant automation that can replace manual labor or at least minimize the physical strain associated with it. Even if a machine can’t replace a job, automation can make a job more comfortable to perform by reducing the amount of heavy lifting and awkward postures. By making jobs less taxing, companies can broaden their potential labor pool.

In a previous article, we discussed recent innovations to boost pallet plant productivity such as robotic dismantlers, automated board trimming/sorting and exoskeletons. In this article, we continue the conversation by exploring some other types of machinery that have been proven to streamline operations and enhance productivity. Let’s take a look.

Lift tables

Lift tables have been used for decades in industrial applications but remain underutilized in the pallet sector. Lift tables have proven to be game-changers in some plants. For example, Pallet Resource of NC installed lift tables in its cut department, and the feedback from workers has been overwhelmingly positive. These tables not only alleviate lower back strain caused by bending but also eliminate risky twisting motions. Raymundo Maya II, a second shift supervisor, shared his experience in Pallet Enterprise.

“It was working well for us and was efficient, so we asked for more,” he said. “Now, pretty much every saw has a lift table.” Lift tables reduce the risk of injuries related to stacking and unstacking boards, leading to increased production and improved worker satisfaction. Despite their simplicity and affordability, many companies have yet to take advantage of this labor-saving opportunity.

Another example discussed in the same article, Durham Pallet introduced Bishamon lift tables along with gravity-infeed conveyors to revolutionize its operations. With this setup, workers never have to bend over, as the stack of pallets is always at table height. By pushing a button to raise the lift table when the stack goes below a certain level, workers can effortlessly access pallets and continue working without strain on their backs.

Conveyors

Do you have idle forklifts in your plant waiting to place a load or to take away a finished stack of pallets? That’s where conveyors can help. Go Fast Manufacturing, for example, offers a variety of roll case and chain-fed style conveyors that can enhance ergonomics and boost productivity.

By utilizing conveyors in front of nailers, trim saws, or notchers, workers can effortlessly stage bundles of components while eliminating forklift wait time. Conveyors, when combined with lift tables, also help reduce bending and lifting, further improving worker comfort and safety.

Board Stackers and Pallet Stackers

Automated stackers are another often-overlooked labor-saving idea for pallet companies. Automated board stackers eliminate the need for manual stacking, freeing up employees for more value-added activities. Aside from board stacking, automated pallet stacking at the end of the repair process can also improve productivity and worker experience.

Regarding pallet stackers, Durham Pallet enjoyed a pallet repair production increase of 20% after it installed a takeaway conveyor and automated stackers at the end of its repair area.

Robotics

Pallet plants are increasingly leaning on robotics for a variety of tasks. At the same time, robots are becoming much easier to use, featuring an intuitive user interface and “Plug and Play” integration. Modern robots are designed with standardized communication protocols and interfaces, allowing for easier integration with other equipment and systems.

In the past article, we looked at robotic pallet dismantlers. However, robots are increasingly used for other tasks such as stacking and unstacking pallets and placing pallet components such as mats, blocks, or deckboards in place on automated nailing lines. Robots can also feed nailing machine hoppers.

With pressure to hold the line on costs and draw upon a larger labor pool, investment in automation can be a big help. Equipment such as stackers, conveyors, lift tables, and robots offer practical opportunities to streamline operations while enhancing worker safety and comfort.

As a leading pallet management company, FALM values its comprehensive network of pallet supply partners and customers across the United States and is always looking to help its partners become more resilient and profitable, especially in tough times. Pallet suppliers interested in participating in FALM’s Preferred Supplier program can click here.